Digital Manufacturing Can Be a Game Changer for the Industry

Manufacturing is the lifeblood of American industry and was once the envy of the world. No other industry can mobilize the nation like manufacturing. America’s response to World War II was the most extraordinary mobilization of an idle economy in the history of civilization. During the war, 17 million civilian jobs were created, there was a nationwide productivity increase of nearly one hundred percent. Corporate earnings more than doubled.

Today, the manufacturing industry is a pale remnant of what it was before inflation and companies moving manufacturing offshore to places like China. But American manufacturing is at a crossroads. US Manufacturing could continue its downward spiral or turn things around in a big way. For American manufacturing to reclaim its international glory of years past, it must embrace the willingness to learn, innovate, and adopt new technologies. Collectively, these technologies are a part of digital manufacturing.

Defining Digital Manufacturing

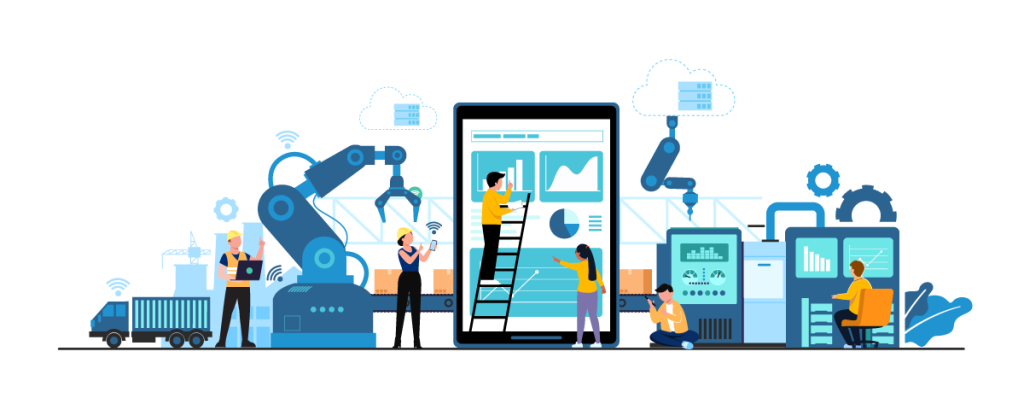

Digital manufacturing is the application of cloud computing systems to manufacturing services, supply chains, products, data collection, warehousing, and processes. Digital manufacturing technologies link systems and processes across the production environment to create an integrated approach to manufacturing. This strategy encompasses everything from design and development to production and servicing the final products. Traditional factories were analog environments where everything was built by hand, have become Smart Factories.

Think of how the basic 1970’s cellphones evolved into the 90’s smartphones—taking a phone that only made phone calls to a mobile computer that can browse the Internet and run software applications. Then in 2007, the hyper-connected iPhone burst onto the scene. From the beginning, the iPhone was like a Swiss Army knife. It included everything you could want to do with a computer-driven gadget. The iPhone is now a professional quality camera and many other things.

Similarly, a Smart Factory is hyper-connected, predictive, and does many things old analog factories can’t do. These next-generation facilities are the core of digital manufacturing. A fully functioning next-generation manufacturing facility is built on cloud computing to optimize operations, store, and process tremendous amounts of data. The rest of the intelligent factory digital platform utilizes AI, big data analytics, automation, and an array of sensors.

Industry 4.0

In 2017, an article in The Economist stated that “The world’s most valuable resource is no longer oil, but data.” Today, data’s expanding amount and role are the driving force in Klaus Schwab of the World Economic Forum first identified as “the Fourth Industrial Revolution” or Industry 4.0. Manufacturers can break down siloed workflows and blend employees’ digital and physical worlds by utilizing technologies ranging from IoT (Internet of Things) to M2M (Machine to Machine) communications. Digital technology can dramatically improve productivity in planning and streamline production processes. It could also help solve another growing problem.

According to a study by Deloitte last year, as many as 2.1 million manufacturing jobs will be vacant through 2030. The report warns that the worker shortage will hurt revenue and production. Positions left unfulfilled could ultimately cost the US economy one trillion dollars by the end of the decade. Skilled labor hasn’t been the only hurdle. Supply chain disruptions and difficulties sourcing raw materials hobble the industry. Digital manufacturing can help fill industry jobs by attracting talent who want to use new technology. These people want real-world experience on digital tech designed to increase efficiencies because they know how valuable that experience will be long-term.

On August 12, 2021, Forbes article, Willem Sundblad writes that even if manufacturers can find what they need, prices are so high that they threaten margins. High inflation is sure to exacerbate the supply chain problem.

The battle cry from leaders in manufacturing is to seek out

- suppliers geographically closer to production centers

- more resilient supply chains

- technology that can help modernize processes

- skilled talent to operate effectively in a next-generation factory setting

Sundblad reminds us that the US is good at innovating but not so good at scaling those innovations compared to other countries. While the manufacturing industry might averse to risk, the American spirit is all about taking a calculated risk, especially when our backs are up against the wall. The window of opportunity is open, but it won’t remain open indefinitely. Remember, things move fast, and the stakes couldn’t be higher for manufacturing to get innovation right. Writing about transforming businesses through technology and innovation, Ethan Karp is the President and CEO of a non-profit manufacturing consulting group called Magnet. In his Forbes article, 4 Reasons 2022 Can Be A Game Changer for American Manufacturing, Karp recognizes the opportunity for American manufacturing.

If American manufacturers can invest in talent, technology, and innovation, they’ll be in a good position to take advantage of available opportunities. Karp identifies five of them. They are:

Take Back the Supply Chain

Use a combination of technology and innovation. Think about the incredible pivots thousands of manufacturers made during the pandemic to meet the demand for Personal Protective Equipment (PPE).

Take Calculated Risk

Karp urges manufacturers to override being conservative and take calculated risks. He suggests ways to mitigate the risk of innovation by asking four questions:

- Are you solving a real problem?

2. Does your product solve the problem?

3. Can you deliver this solution?

4. Can you sell it?

Invest in the Smart Factory of the Future

Take whatever capital is available and invest in the technologies used in a Smart Factory. These technologies are the most direct way for manufacturers to excel in a competitive and dynamic marketplace. Over time, Smart Factories lower costs by speeding up processes, reducing downtime, and minimizing waste. These digital innovations will improve supply chain efficiencies.

Automate to Offset Talent Shortages

Karp emphasizes the importance of automation by sharing the story of Gojo, the company that invented the hand sanitizer Purell. The family ran operation successfully tripled its production almost overnight to meet pandemic demand. The company was ready because of its investments in Industry 4.0 technology over the years. Gojo has automation to do repetitive tasks and frees employees to do more value-added technology work, like programming and running the machines. The company hired 500 new people in 2020.

Capture the Infrastructure Boost

Manufacturers like steel and transportation suppliers will be kept busy with the government-sponsored trillion-dollar investments in transportation and public safety. Karp offers two recommendations:

- Evaluate margins to provide a buffer against the unknown

- Have the technology and talent already in place to manage production surges.

As accurate as the threat of digital disruption is, future success is more about making informed decisions with a view of the long-term consequences. Leadership is about establishing a direction and vision for the future, aligning people around that vision, and motivating and inspiring them to take action. Making better choices is a necessary ingredient.

In the February 2022 Harvard Business Review article, How Incumbents Survive and Thrive, Julian Birkinshaw looks at how Fortune 500 companies remain stable despite disrupters. “When companies face a disrupter, their natural response is to fight fire with fire: to set up a competing digital unit, build an incubator or accelerator, or pursue a transformation.” He cites a McKinsey study that found “companies that adopt bold, offensive strategies in the face of industry digitization improve their odds of coming out winners.”

Companies must embrace digital technology to improve operational effectiveness. The global utility Enel has a division that experiments with new business models (demand management and electric vehicle charging). The unit is called Enel X and has enormous growth potential. However, it currently represents less than two percent of the parent company’s revenues. Everyone else at Enel focuses on optimizing the existing business and providing its nearly seventy-two million customers with high-quality service. But the new technology in its factories and distribution networks, including reengineering its infrastructure and processes, that went into Enel X has bolstered operations throughout the organization. For technology to help manufacturers succeed, leadership should take the time and energy to develop an adaptation strategy that best fits their organization’s unique needs and capabilities.

Considering how Digital Manufacturing and the Smart Factory of Industry 4.0 can help you streamline workflow, be better positioned to seize opportunities, and maintain margins. Don’t start out by going for the big objective. Start with low-hanging fruit. Even still, before beginning any digital manufacturing initiative, understand the technology. Learn what technologies perform what types of tasks and the strengths and weaknesses of each. If you have a chief technical officer or IT director, get them involved in discussions as soon as possible. Suppose people in the IT department have a good understanding of the different Smart Factory technologies. In that case, they’ll save the company wasted time and money pursuing the wrong technology. They’ll also help prevent making technology choices that don’t fit the company objectives. Again, the real tipping point is the willingness to learn.

If you don’t have information technology or data science capabilities on staff, build a team of external service providers. Having the right pool of resources is essential.

The Key Areas of Digital Manufacturing

Cost Reduction

Utilizing cutting-edge technologies to optimize processes can result in financial efficiencies within a manufacturing operation.

Enhanced Customer Experience

Customer-facing technologies help give the customer transparency into the manufacture of their product and ease of communication and collaboration with the manufacturer.

Provisioning of Resources for Employees

A modern workplace nurtures better employee satisfaction and retention rates. The next generation of employees has grown up with high-impact technologies. They expect the deployment of quality effective technologies within their working environments.

Innovation

Traditional manufacturing and production methods are undergoing digital transformation. Going beyond production automation, the Information and Communications Technology (ICT) found in Industry 4.0 blurs the boundaries between the physical world and the virtual in cyber-physical production systems (CPPSs). A report from Deloitte describes CPPSs as online networks of social machines organized like social networks. They link IT with mechanical and electronic components that communicate through a network. Smart machines continually share current stock levels, problems, and changes in orders or demand levels.

Improved Operational Efficiency

Although last on our list, operational efficiency is the biggest “selling feature” of the move toward Digital Manufacturing strategies. By digitizing operations, data can be collected, categorized, and analyzed at every stage – from raw materials to finished and delivered products. The utilization of this data then allows your manufacturing firm to use agile cycles to grow and scale.

Digital Manufacturing Isn’t Just for Global Giants

Most manufacturers across the country have engaged in a digitization effort. That digitization allows their CIOs to develop digital transformation strategies to help their manufacturing operations inch closer and closer to Industry 4.0 ideals.

In Conclusion:

Digital Manufacturing is a genuine game-changer for the industry. To say there are many benefits to digital manufacturing is an understatement. The hyperconnected Smart Factory merges complex manufacturing processes across different departments. Smart Factories eliminate the paper-based process and automate data exchange in fractions of a second. Communication and collaboration going in all directions simultaneously far extend the reach of any manufacturer. What is more, digital manufacturing inspires people to learn and innovate on a much higher level.

Every manufacturer is at a different stage of their Digital Manufacturing journey. The decision to convert traditional factories to smart facilities requires deep engagement with the entire company. Set priorities and create a portfolio of projects. But keep this in mind; the benefits are well within the grasp of even small to mid-size operations. Remember the story of Gojo and how they routinely invested in modernizing their operations. Not all at once but over time. When the time came, regular investments in technology made all the difference. Using smart and autonomous technologies, CIOs are blending the physical and digital worlds while making the most of human resources along the way.